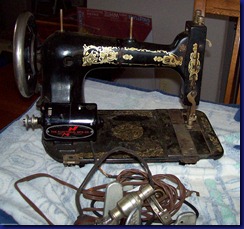

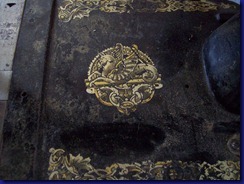

Hello everyone. I sincerely apologize for my overly extended absence. I could go into the details as to why, but that would be boring. Instead we’ll just jump right into the reassembly of Ms. Rusty!

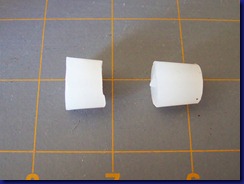

We left off last time installing the Connecting Rods. The next step I tackled was the Feed Lifting Rock Shaft, or FLRS as I affectionately call it. The next two photos show all the pieces/parts needed to install the FLRS.

Parts laid out in approximately correct location when assembled. It took me a bit to figure this out as I’ve been away from Ms. Rusty for so long!

The first step is putting one half of the feed dog raising mechanism on the left end of the shaft as shown below – be sure to put it on facing the right way (screw toward the inside of the machine)

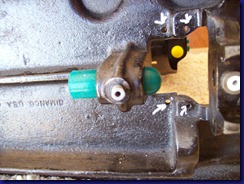

The mechanism at the right end of the FRLS (Feed Lifting Rock Shaft) is used to raise or lower the feed dogs. The pictures below show the position of the second half (front/left half) )when the feed dogs are raised and lowered. Honestly, I’m not sure which one is represents raised or lowered. I could make an educated guess, but I’m sure I’ll figure it out after the feed dogs are installed. The screws will also have to be adjusted a bit after the feed dogs are in to make sure they are at the correct height for sewing.

At this point the rod is ready to put into the base of the machine. Lay the machine on its side with the bottom facing you and the balance wheel end to the right. The FLRS attaches to the top legs in the base. Put the two “pointy” screws partially into the legs on the machine base on both the right and left side. The photo below shows a “pointy” screw in the right leg of the base.

Place the FLRS bar between the screws and tighten a bit. You don’t want the bar too tight, just enough to hold it, as you need some room so you can attach it to the connecting rod. Attach the end of the feed connecting rod (installed here) to the FLRS via the taper hole. The connecting rod should be towards the balance wheel and the nut towards the bobbin area (see photo below).

Tighten or adjust the end nuts and taper nuts as needed so when the balance wheel is turned by hand the connecting rod doesn’t bind or drag, nor have too much play. It isn’t too hard to do this. It’s pretty obvious that you need to move/adjust the FLRS one way or the other if you can’t even get the connecting rod to butt up against the taper hole. This is what happened to me on my first try. Once I had things lined up right, everything just slid into place. After that, only minor adjustments were needed to make it rotate smoothly. It seemed to me that if it didn’t feel/look right, it probably wasn’t right.

Here is a photo of the bottom side of Ms. Rusty with the FLRS fully installed.