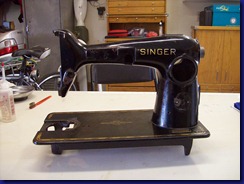

Well, the heat of summer has taken its toll on me and Ms. Rusty. It’s been too hot to work in the garage the past several weeks, not to mention I’ve had a

huge project due at work that kept me from doing much tinkering. As a result, Ms. Rusty hasn’t been getting much love lately and has punished me by rusting again.

To be fair, she didn’t have much choice in resorting to rust given that I hosed her down with water after her last Evapo-Rust treatment. My mistake was that I didn’t give her another quick dip in the stuff to coat her surfaces to prevent rust from reoccurring. Here are some photos that show the result of my neglect.

Initially I wasn’t too worried because I thought I would just sandblast all the rust off. Then after a few days of denial I came to my senses and realized that there are some parts that will NOT get sandblasted, such as thread fittings (as in screw threads, not fabric threads). That’s when I decided Ms. Rusty needed another bath.

This time I opted not to do mop bucket method, like last time. While that worked ok, it required more Evapo-rust than was really necessary to get all of Ms. Rusty submerged. Instead, I did the “bag-in-a-bucket” method (I made that name up just in case you are wondering).

Update: I can't take credit for inventing the "bag-in-a-bucket" approach. I saw the concept first mentioned on one of the Yahoo! Groups I belong to. Coincidentally, Dragon Poodle outlined a very similar approach on her blog the same week as this post (http://dragonpoodle.blogspot.com/). I wish I had seen her post prior to giving Ms. Rusty her second bath so I could have used some of her tips, like using bubble wrap instead of towels and a sweatshirt :)

I started off with one bag in a short bucket, like so:

While it might have been ok, I was concerned with the height of the bucket not being sufficient to hold the Evapo-Rust (ER) if it happened to leak out. That then made me think that maybe 1 bag wasn’t enough. So I went to plan B – triple bag in a tall kitchen trash can.

I then poured a gallon of ER on top of Ms. Rusty, but this only covered her rear arm.

So, to displace some of the air and make the fluid rise up higher, I tied up the bags and stuffed towels and an old sweatshirt (just happened to be on my workbench at the time) around Ms. Rusty outside the bags . It worked pretty well as the ER ended up covering over half of Ms. Rusty.

Mummified Ms. Rusty -

After a 90 minute soak, I took out the towels and other stuffing and unwrapped the bags. Surprisingly there were no leaks! I then turned Ms. Rusty over on end to make sure her other side got the ER treatment. Again, I tied up the bags and stuffed towels and such around her to make the fluid rise to the level I wanted. After another 90 minute soak she was done.

This time when I took out the towels they were more than damp so a leak had sprung somewhere during the second soaking step. However, most of the ER liquid was still in the bag. After wringing out the towels in the bucket and returning that, along with the “bag” liquid to the ER container, I ended up with a nearly full container!

Ms. Rusty was placed on my workbench and was NOT rinsed off. I did wipe her down with a towel, but I left the residual ER to help prevent the return of any surface rust. She definitely looks better after her second soak and is ready to be prepped for sandblasting.

Hopefully it will cool down a bit this weekend so I can spend more quality time with my old girl. There is a lot of prep that needs to be done to plug up threaded holes and machined edges that should not be exposed to sandblasting. My goal is to get that part done before I go on vacation in 10 days. We’ll see……