I recently acquired a few “new” machines. My father-in-law went to a swap meet to look at old automobiles, but ended up buying a few sewing machine treasures for me rather than car parts for himself. My mother-in-law calls him a “pusher” for my addiction (lol). I like what he is pushing so I’m not about to complain!!

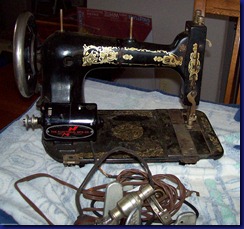

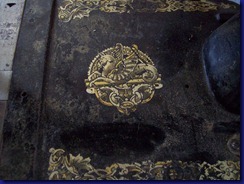

New Wilson manufactured by the A.G. Mason Manufacturing Company in Cleveland, Ohio. It’s a shuttle machine and came in a bentwood case. My FIL has the case right now to repair the latch so here are pictures of the machine without the case. I don’t know if it originally had a motor, but I strongly suspect the motor on it now is a replacement or aftermarket model.

The A.G. Mason company was only in existence from 1903 to 1916, so this machine is about 100 years old. Other than learning that the A.G. Mason company was acquired by the Domestic Sewing Machine Company in 1916, I don’t know anything else about the New Wilson sewing machines, so if any of you out there know more, I love to hear about it!

Singer Treadle

The serial number on this machine is AA-738142 so information available on the ISMACS website indicates that this baby is a Model 66 made in late 1925. The decals on this machine are in really good shape and the cabinet is also in good condition. It has some surface rust on the chrome parts, but unlike Ms. Rusty, this machine can actually make a decent stitch in it’s present condition. It shouldn’t take much to get her looking good and running great!

Singer 306k

This one I can’t blame on my FIL. I bought this one myself at a yard sale. It is a 306k and probably the newest model Singer in my collection. I can’t find a thing wrong with the machine at this point and it just needs a bit of cleaning to be in great condition. The cabinet is also in pretty decent shape, but could use some refinishing to get rid of some wear marks and scratches.

As you can see, I will have plenty of projects to work on when Ms. Rusty is finished. The two biggest questions on my mind at this point are: 1) will I EVER finish Ms. Rusty? and 2) which project should I start on next?